Invention / Innovation

Dragon Coating Limited (DCL) is a diversified company that brings innovation and services that provides customised solutions in a wide array of vertical markets, including watches, jewellery, daily consumer goods and even housewares.

DCL “Dragon Sapphire Coating” (DSC) provides an ultra-thin utmost protection layer (up to Mohs 9) on metal substrates at an affordable cost, while virtually eliminating abrasion and corrosion.

DCL is committed to advancing photonics and sustainable technologies and

business practices to meet the needs of brands and manufacturers.

Backed by

unparalleled expertise in optical physics, metal and material science, we apply

environmentally friendly technologies with the Physical Vapour Deposition (PVD) technique

and we develop products in almost every industry to protect our customers’ belongings.

Physical Vapour Deposition (PVD):

Physical vapour deposition (PVD) is a standardised, mature industrial method that produces a thin layer of materials onto some substrate surfaces, such as glass, metal, plastic and so on. This thin layer of materials is normally manufactured in a chamber of high vacuum in a clean laboratory environment.

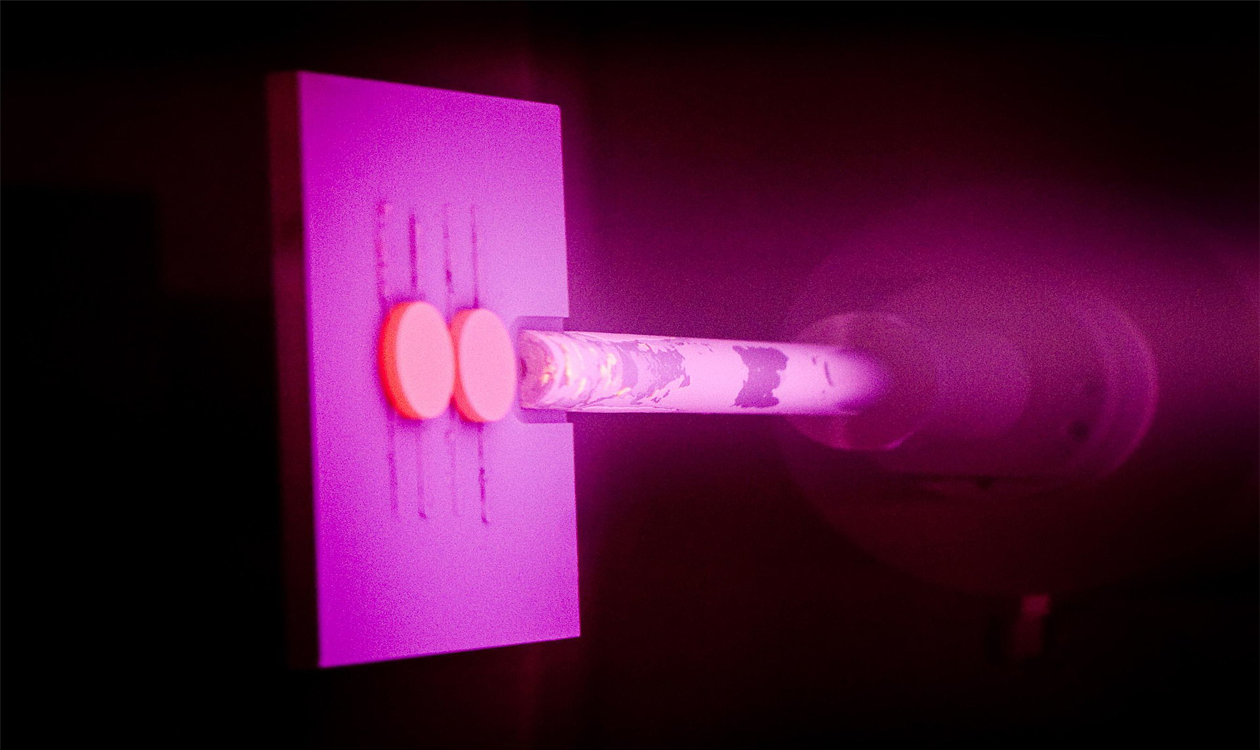

Sputtering:

There are various ways of producing PVD materials, such as through heating and vaporizing the target sources. The method we use is referred to as "sputtering", which "sputters" the target materials to the substrate surfaces by means of plasma. Even though plasma may heat up the substrate surfaces, the entire sputtering system can be kept at room temperature with maximum temperature not exceeding 35 ºC, which provides an ideal environment for materials sensitive to temperatures.